Mechanical System Design & Analysis & Production

The outer shell and mechanical parts of the products designed in line with the demands of the customers are designed and produced using three-dimensional modeling and virtual engineering calculation techniques in accordance with all external environment requirements (related IP and MIL standards such as MIL-STD-810, MIL-STD-461 etc.). Mechanical designs that meet environmental requirements are made in accordance with military and industrial standards within FANKOM Engineering.

Mechanical Design

Mechanical System Design and Mechanical Modeling

Mechanical designs, which are a determining element of product visuality and functionality, are realized with 3D design tools in line with customer requests at all stages from concept design to the final product.

The suitability of the designed and developed products for the target audience, their appearance, etc. elements are determined at the industrial design stage. The rapid maturation of the product in the process, the contributions of the mechanical designer, provide the right product and product features to be revealed. Mechanical Design is perhaps the most important part of the product development process.

In the beginning, the details of the product that may occur in the future are discussed and predicted together with the industrial designer, then the production-production criteria are examined, etc. elements have a serious importance in the process. For this reason, we create all our mechanical designs with the technical contributions of our industrial designers.

In the Product Development process, mechanical design should proceed simultaneously with subsequent engineering studies, as in the industrial design phase. Before the product comes to the manufacturing-production stage, material selection, mechanical properties, manufacturing-production selection and molding method etc. criteria are studied and evaluated in a 3D computer-aided design environment, and their verification is done. All these details are solved at the mechanical design stage.

In addition, our electronic designs; It is evaluated as a part of mechanical design and modeled in 3D. This situation allows the perfect harmony of electronic and mechanical parts with each other and with the peripheral units during the design and to intervene when necessary.

The outputs obtained during the design phase are implemented with rapid prototyping, so that both visual elements are examined and the compatibility of interrelated parts is tested. In addition, with rapid prototyping, design-related errors encountered in high-cost tooling productions are prevented, mass production assembly difficulties can be foreseen and production efficiency is increased.

All designs; It is carried out by considering customer criteria, production technique and relevant standards, from material selection to the paint to be used, from its behavior in environmental conditions such as temperature and humidity to the requested IP standards.

Mechanical Analysis

As FANKOM Engineering, we provide advanced engineering services within the following sub-titles under the umbrella of Mechanical Analysis:

Structural strength analyzes

Fatigue, fracture, natural frequency, regulatory compliance analysis

With Finite Element Analysis (FEA), strength, fatigue, vibration, explosion, shock, tipping, collision, earthquake, heat transfer, metal forming, electrostatic and electromagnetic, design optimization etc. in various parts and systems. engineering services in accounts

Dynamic analysis

Determination of the dynamic behavior of the structure under operating conditions

Engineering services in rigid and flexible body dynamics (MBD) and motion simulations

Engineering services in rigid and flexible body dynamics (MBD) and motion simulations

'

Computational Fluid Dynamics (CFD) Analysis

Reducing pressure losses, improving flow channel

With CFD simulations, heat transfer, mixing, combustion, turbo machines, HVAC, hydrodynamics, aerodynamics, aeroelastic, smoke and gas distribution etc. in internal and external flows. engineering services in calculations

Determination and improvement of thermal load distribution in buildings

Mechanism Analysis and Optimization

Mechanism study analyzes and simulations

Engineering services in the fields of construction, sizing, simulations, analysis, performance optimization studies of functional models of jet and turboprobe engines in aircraft and internal combustion engines in land vehicles

Weight reduction and cost reduction analyzes

Mechanical Systems Engineering

Modeling and simulation studies of mechanical, hydraulic, electronic and mechatronics subsystems on all platforms with mechanical systems engineering and model-based design approach

Engineering services for controller development / development of control models for these systems

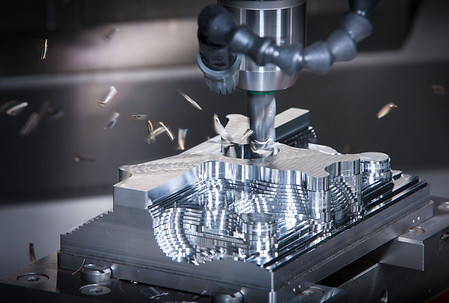

Mechanical MFG

We offer solutions to our customers from the prototype production stage, which is required in the verification process of the projects. The design and manufacturing needs of prototypes of parts, products, systems and subsystems are quickly met with FANKOM Engineering and its solution partners for mechanical production.

It is aimed to produce defect-free products by considering the processes and quality requirements during prototype production and by keeping in constant contact with the customer.

FANKOM Engineering provides consultancy services in the operation of the following mechanical production processes, mechanical system integration and prototype production:

MECHANIC CNC MANUFACTURING

LASER CUT PRODUCTION

SHEET METAL SHAPING

Machining of mechanical parts is carried out as soon as possible according to customer requirements. According to customer requirements, precision mechanical production and precision mechanical assembly services are offered together or separately. Traceability is ensured before, during and after production, and necessary quality assurance conditions are fulfilled according to customer requirements.

3D Printing services

Our 3D Printing Services take any object shot in any 3D software package and transform it into a solid plastic model. This model allows customers' requirements to be translated into a 3D prototype model by attaching the tested parts during the prototyping process. As part of our 3D printing service, such a process ensures the accurate production of a functional final product that can be delivered to market.